Known as the “Switzerland of Bahia” for its mild climate, cooler than the region’s average temperatures, Maracás, located in the state of Bahia, has a large vanadium field that contributes to the development and economy of the entire region.

Vanadium is an important metal used mainly for producing stainless steels for surgical instruments, tools, and corrosion-resistant steels.

The city of Maracás is the headquarters of Vanádio de Maracás, an important mining company part of the Canadian group Largo Resources and considered the only vanadium producer in the Americas and the best operation of this ore in the world.

With an expressive participation in the Northeast region, as well as in all of Brazil, Mercurio Conveyor Belt has built over the years a successful partnership with Vanádio de Maracás that goes beyond the supply of quality conveyor belts, because it also involves specialized customer service, continuous training, and frequent technical visits.

An opportunity in sight

At one of these visits at the end of 2018, Celso Teixeira Veiga, Mercurio’s salesperson then responsible for doing business with this company, and Genival Alves de Souza, his Technical Assistant at the time, identified a new opportunity at the mining company. “We were giving training on splices when we found out that an important conveyor belt was having many problems and directly impacting the mining operation,” says Celso Veiga.

Vanádio: Magnetite ore

The conveyor belt in question is a key piece of equipment in the operation. “It is responsible for transporting the magnetite, the ore containing the vanadium, directly from the primary crusher just after passing through the mine’s blasting process,” explains Isidoro Pimentel, Mechanical Maintenance Supervisor at Vanádio de Maracás.

Magnetite Rock, the ore containing Vanadium.

In these conditions, the conveyor belt receives large, pointed rocks that end up quickly causing rips and reducing its expected service life. “The raw magnetite rocks loaded by the belt supplied by the competitor were causing a lot of wear. The damage was so large and so fast that Vanádio de Maracás reached an average of four downtimes for changing belts in just one year,” says Celso.

Soon after, Mercurio‘s Team began to run tests in order to develop a new solution that would meet the customer’s needs and expectations, which was a more resistant conveyor belt capable of eliminating two changes a year. The new conveyor belt would have to have a service life 100% longer than before and thus reduce costs, reduce maintenance downtime, and increase the productivity of the customer’s equipment.

Superior performance

Through a joint effort that involved the Sales, Application Engineering, and Technical Assistance areas, in the second half of 2019 Mercurio delivered what it considered to be the ideal solution to solve the customer’s specific problem: the MercoRip Conveyor Belt.

“We went to the field and based on the specifications given by the customer and the characteristics of the material transported, we developed a conveyor belt with specifications unique to Vanádio’s needs”, recalls Veiga.

Mercurio’s MercoRip conveyor belt features a unique solution with a special-compound cover, making it highly resistant to rips and impacts along with excellent abrasion resistance. MercoRip was specially developed to increase the service life of the belts in high impact conditions such as those presented by the Vanádio’s belt.

“Since the beginning we were sure that MercoRip would be the ideal solution to replace the conveyor belt that was deteriorating very quickly. Our product was designed to reduce the cost per ton transported by increasing the equipment’s operating time,” explains Veiga.

Thanks to the field work and commitment from the entire team during the process, in addition to the company’s recognition for the quality and confidence in Mercurio, the suggestion presented was promptly approved. “We had done a very careful job with the follow-up of two Vanádio de Maracás Coordinators throughout the process. Our project was so well tested that when we presented MercoRip in the second half of 2019, the solution was quickly accepted by the mining company’s professionals”, he adds.

Mercorip conveyor belt in action

In April 2020, Vanádio de Maracás installed the MercoRip Conveyor Belt in the place of the previous belt and the result not only met its initial goal, but exceeded expectations.

MercoRip presented excellent performance in the most critical conditions. Thanks to its specification with the combination of the cover that is highly resistant to rips and impacts along with a stronger reinforced carcass compared to conventional ones, MercoRip has presented a superior performance with a longer service life than the 6 months previously established by the customer.

“To increase resistance even further, we added the Rip Proof protection system, an aramid shock-absorbing textile located between the carcass and the cover, which ensures even more protection. This decision proved to be spot on since the belt received not only friction from the rocks, but also from many impurities such as pieces of metal, for example”, explains Veiga.

Os resultados da MercoRip

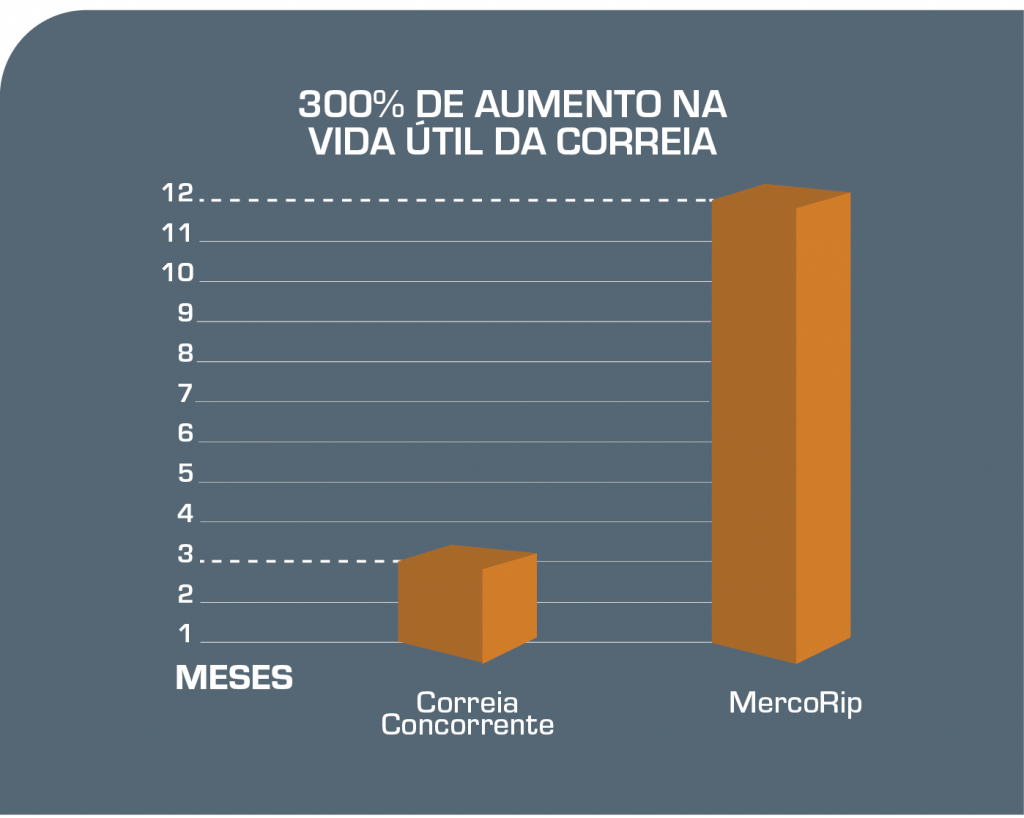

Compared to the previous belt, the the perfomance is already four times higher, that is, a 300% increase in service life.

Compared to the previous belt, the performance is already 4 times higher, which is an increase in service life of 300%.

During its first year of operation, MercoRip had to be changed only once compared to the average 4 changes of the competition’s conveyor belt. “We were very pleased with the result presented. In addition to the belt’s own characteristics, the aramid textile, Rip Proof, proved to be very efficient in its protection, avoiding the perforations that occurred in the previous belts”, confirms Isidoro Pimentel.

According to the customer, the corrections made to the conveyor system, as pointed out by the Mercurio team, such as replacing stands and correcting the installations of the skirt boards, were also very important for the operation’s success.

Knowledge, responsibility, experience, partnership, and commitment to the customer’s productivity and success: this is the recipe from the largest conveyor belt manufacturer in Latin America to transform the offer of a new conveyor belt into a new success case.

“The result achieved and the customer’s satisfaction prove the correct choice for MercoRip. I’m sure we are still going to build many stories with Vanádio de Maracás,” concludes Celso Veiga.